últimas noticias

-

¡La raqueta Double Fish Defense Pickle Ball obtiene la aprobación de la USAPA!

-

Pelota de tenis de mesa hueca con grabado artesanal de pez doble: un puente cultural que conecta a China y el mundo

-

Los productos de tenis de mesa de Piscis fueron testigos de la primera medalla de oro en tenis de mesa de dobles mixtos de Wang Chuqin/Sun Yingsha en los Juegos Olímpicos de París.

Categorías de Producto

Caliente Productos

-

Tabla de Tenis de Mesa Premium para Campeonatos Volant King

Esta mesa de tenis de mesa premium es apta para campeonatos. Aprobado por la ITTF y NSCC. Tren de rodaje de plata + luz azul

Lee mas -

Mesa oficial de tenis de mesa para el torneo Volant Dream 2

Mesa de ping pong oficial Volant Dream 2 para competiciones internacionales diseñadas por Double Fish Sports.

Lee mas -

Mesa Oficial de Tenis de Mesa para Competitons XIANGYU 328

Tabla plegable doble superior del tenis de vector, diseño compacto El nuevo sistema de plegado minimiza el riesgo de lesiones durante el almacenamiento y el movimiento de la mesa. Tabla de tenis de mesa aprobada por la ITTF.

Lee mas -

Mesa oficial de tenis de mesa duradera para el World Tour 99-45B

La ITTF aprobó una mesa de ping pong duradera oficial para un torneo internacional. Espesor del tablero de mesa: 25 mm CALIDAD DEL TORNEO - Esta mesa de nivel profesional está diseñada para el más alto nivel de competencia. PERFECT FOR FAMILIES: ofrece juegos premium para todas las edades. Vaya cabeza a cabeza o pliegue para practicar individualmente. Los soportes de acero de calibre grueso de 2 pulgadas cumplen con los desafíos más difíciles. Un gran centro de mesa para su sala de juegos, estudio o gimnasio. FÁCIL ENSAMBLAJE: comience a jugar en minutos con un simple ensamblaje. La red de alta calidad está equipada con abrazaderas de bloqueo que se unen fácilmente.

Lee mas -

Mejor calidad doble pescado V40 + Volant 3 estrellas pelota de tenis

Doble pescado V40 + Volant 3 estrellas bola de tenis de mesa es confirmar a los últimos estándares técnicos de la ITTF T3.

Lee mas -

Double Fish QIJI Lámina para tenis de mesa

Doble pescado QIJI todo terreno de tenis de mesa, que es la mejor tabla de tenis de mesa de tenis de mesa, & nbsp; Perfecto para el jugador allround tradicional

Lee mas

Rastreando el origen | Desarrollo de la fábrica de tenis de mesa de Guangzhou (Parte 2)

Desde el otoño de 1960, Chenggong Table Tennis Factory dedicó más de dos años a la innovación tecnológica, que básicamente mecanizó los principales procesos de producción de la fábrica a finales de 1963, mejoró la producción y la calidad del producto y comenzó a exportar productos. En 1963, la producción fue de 3,2 millones, más del triple de los 780.000 de 1960, de los cuales se exportaron 58.400.

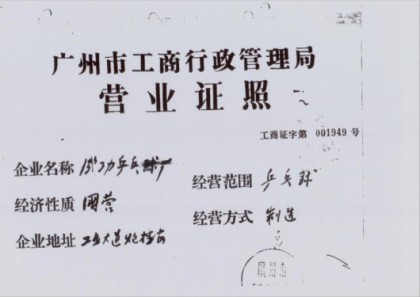

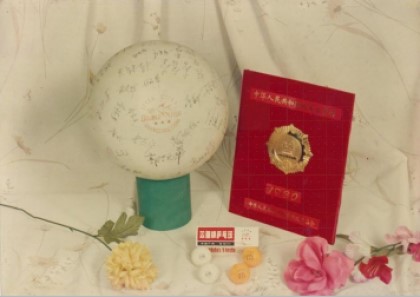

Licencia comercial de la fábrica de tenis de mesa Chenggong

① El contenido de este artículo se basa principalmente en los datos históricos de Chenggong Table Tennis Factory y las páginas 303-304 del Volumen 5 (Parte 1) de "Guangzhou City Chronicles".

Sin embargo, justo cuando la producción de la fábrica de tenis de mesa Chenggong estaba en auge, la escasez de recursos hídricos en el área del Templo del Polo se convirtió en un nuevo problema que restringió el desarrollo futuro. Al final, el departamento superior decidió trasladar la fábrica de tenis de mesa Chenggong a Paolougang, junto a la avenida industrial Henan ②, para resolver el problema de la escasez de agua y ampliar aún más la escala de producción. Esta reubicación marcó el comienzo de un nuevo capítulo en el desarrollo de Chenggong Factory.

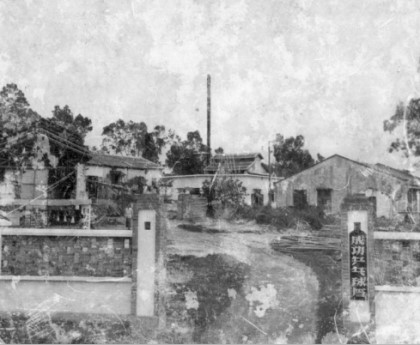

La fábrica de tenis de mesa Chenggong se traslada a Yanzigang, distrito de Haizhu

②Paolougang, junto a la avenida industrial de Henan, ahora es el área de Yanzigang en el distrito de Haizhu. A partir de 1952, el suburbio de "Henan" en Guangzhou se construyó como una importante base industrial en Guangzhou. Esta avenida fue alguna vez el corazón de la industria de Guangzhou y dio origen a muchas novedades nacionales. En su apogeo, la Avenida Industrial de 5,5 kilómetros de largo producía productos que eran populares en todo el país, como refrigeradores Wanbao, baterías Tiger Head, bicicletas Wuyang, etc. El terreno donde se mudó la fábrica de tenis de mesa Chenggong era originalmente una fábrica de cerámica. , que ya contaba con instalaciones fabriles básicas, lo que proporcionaba comodidad para ampliar la producción. Con el fuerte apoyo de la unidad superior, Chenggong Table Tennis Factory pudo comprar un terreno e iniciar la construcción, sentando así una base sólida para el desarrollo futuro.

En 1965, la fábrica de tenis de mesa Chenggong logró otro éxito al desarrollar la primera máquina fotoeléctrica para pesar pelotas de mi país. Luego fabricó sucesivamente máquinas automáticas de medición del centro de gravedad, máquinas automáticas de impresión de marcas, máquinas automáticas de corte de bordes y máquinas automáticas de medición, etc., y tomó la iniciativa en la realización de la producción de tenis de mesa semiautomática y automática en la misma industria a nivel nacional. En 1966, la producción de pelotas de tenis de mesa superó los 10 millones. Durante la "Revolución Cultural", se fusionó con algunas fábricas y también produjo tiristores.

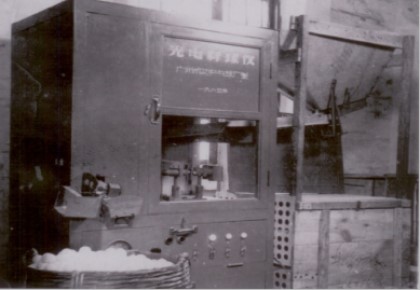

In 1965, Chenggong Table Tennis Factory pioneered my country's first photoelectric ball weighing instrument.

Automatic label printing machine developed by Chenggong Table Tennis Factory

In 1968, with the support and coordination of the local government, Chenggong Table Tennis Factory merged with Huada Badminton Factory③ and Zhendong Sports Goods Factory④ , significantly improving the productivity of the enterprise. Subsequently in 1969, the factory was renamed Guangzhou Sporting Goods Factory, marking the expansion of its product categories and business scope.

③According to the "Chronicles of Guangzhou City", the production of badminton in Guangzhou began in the early 1950s. With the rise of badminton, the production households continued to develop and gradually organized themselves. In 1956, the Yongjian Badminton Production Cooperative and the Yufeng Production Cooperative were formed. In 1960, the Yongjian Society was renamed the Huada Badminton Factory, with 100 employees. In 1964, the World Games brand badminton of the Yufeng Society was rated as a famous brand product in Guangzhou. During the "Cultural Revolution", all badminton production cooperatives were merged into the Chenggong Table Tennis Factory.

④Zhendong Sports Goods Factory mainly produced wooden-handled skipping ropes, table tennis nets, and volleyball nets. Before the merger, the two factories were located on the streets in the urban area, with scattered and narrow factory buildings (all old residential buildings), making material transportation and management extremely inconvenient. The merger improved the production conditions of such products. This article is compiled based on the oral narration of the retired leaders of Guangzhou Table Tennis Factory.

In 1972, the company was renamed Guangzhou Table Tennis Factory. In the same year, Guangzhou Table Tennis Factory introduced the innovative wax expansion method, replacing the old steaming process for producing close-seam balls, which doubled the work efficiency. The introduction of this technology not only improved production efficiency, but also made Guangzhou Table Tennis Factory the first company in China to achieve full mechanization of close-seam ball production.

Table tennis ball expander from the mid-1970s

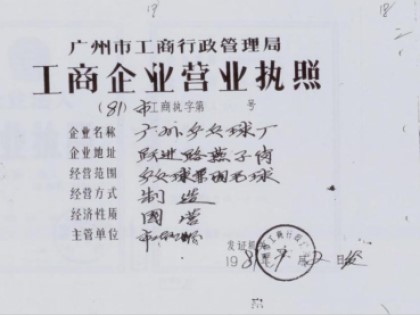

Guangzhou Table Tennis Factory Business License

In 1974, after five months of unremitting efforts and more than 130 precision tests, the Guangzhou Table Tennis Factory successfully developed China's first hard table tennis ball. This achievement marked a major breakthrough in China's table tennis manufacturing technology. The product was subsequently named "Shuangyu Brand". In 1979, this table tennis ball was officially approved by the International Table Tennis Federation and became the designated ball for international official competitions.

In 1980, "Double Fish" brand table tennis balls were officially rated as a national famous trademark and won the National Gold Award in the same year.

Doublefish table tennis won the national gold medal certificate

In 1981, with the booming domestic and foreign markets for badminton, the Guangzhou Table Tennis Factory restarted the production of badminton with the formal approval of the competent authorities. It focused on creating special balls for high- and mid-end competitions, strictly selected high-quality white goose feathers, and used imported cork and artificial leather as ball head materials to produce badminton with excellent whiteness, strong flight stability, and precise landing points. All products were sold to the Japanese market.

From 1986 to 1990, the annual output of badminton achieved an average high growth rate of 31%. In 1989, advanced Japanese production equipment was introduced, which greatly improved the production capacity and reached an annual production capacity of 24 million. In 1987, the Jinque brand badminton in the domestic market was rated as a high-quality product by the Ministry of Light Industry, and in 1990 it won the official certification of the national competition ball, marking the full recognition of product quality and technical level.

In 1986, as sales continued to expand, Guangzhou Table Tennis Factory set up branch factories in Zengcheng and Huaxian (now Huadu District, Guangzhou), focusing on producing mass-market table tennis balls to meet domestic market demand, while the main factory was committed to producing mid- and high-end table tennis balls for export. In 1987, total production soared to 63.02 million, of which 54.82 million were sold to overseas markets, generating US$2.18 million in foreign exchange revenue.

In 1988, the outstanding performance of Guangzhou Table Tennis Factory won the honorary titles of Provincial Advanced Enterprise and National Second-Class Enterprise. In 1990, Guangzhou Table Tennis Factory invested 2.5 million yuan in factory construction and technical transformation to further improve production capacity. In November of the same year, a new celluloid sheet plant was established in Zengcheng with an investment of nearly 2.57 million yuan. Through this series of transformation and expansion, the annual production capacity of table tennis balls doubled from 60 million to 120 million, making Guangzhou Table Tennis Factory one of the important bases for table tennis ball production in the world.

Guangzhou Table Tennis Factory in the 1990s

In 1994, the company relocated and expanded again⑤, requisitioned 50 mu of production land in Dabu Management District, Mayong Town, Dongguan City, relocated and renovated it, expanded its production scale, and achieved rapid improvement in production quality, laying a solid foundation for the company's sustainable development.

⑤ Dado que el componente principal del celuloide, la materia prima para la producción de tenis de mesa, es la nitrocelulosa, este material es extremadamente inflamable y ha causado muchos accidentes de incendio graves en China, incluidos los accidentes de incendio en la fábrica de tenis de mesa Double Happiness en Shanghai y Tianjin. Fábrica de Tenis de Mesa. El 14 de octubre de 1993, la fábrica de tenis de mesa de Guangzhou también sufrió un incendio que provocó el incendio de 4.000 metros cuadrados de edificios. Además, el rápido crecimiento de las áreas residenciales cerca de Yanzigang en la década de 1990 hizo que los riesgos de seguridad en el área fueran cada vez más prominentes. En vista de esto, la fábrica de tenis de mesa de Guangzhou decidió reubicar completamente su línea de producción y trasladarla a Dongguan para garantizar mayores estándares de seguridad y eficiencia de producción.

Fábrica de Dongguan en la década de 1990

En 1995, basándose en la importante influencia de la marca "Doublefish" , la fábrica de tenis de mesa de Guangzhou cambió oficialmente su nombre a fábrica de artículos deportivos Guangzhou Doublefish.

El 26 de febrero de 1998, Guangzhou Shuangyu Sporting Goods Factory se fusionó con Guangzhou Shuangyu Sporting Goods Group Co., Ltd.

+8620-84319554

+8620-84319554 +8620-84328948

+8620-84328948

+86 13829778212

+86 13829778212